Self-Rising Pizza Crusts – Bicarbonate Applications

Pizza is poised to take over the hamburger as the most popular American “fast food.” Pizza has undergone some significant changes in recent years much like other popular food products.

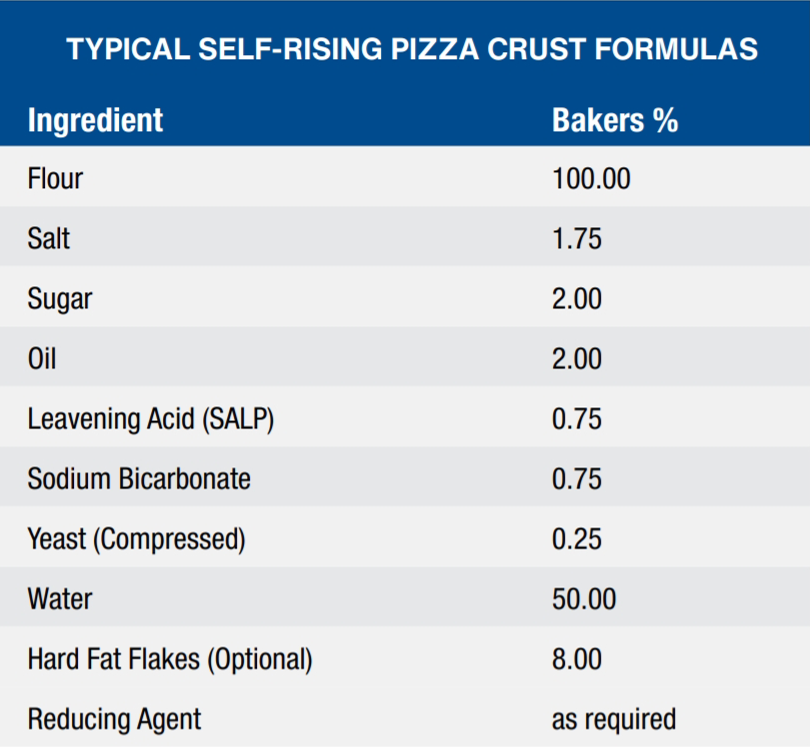

Pizza crust is the major component of the finished pizza product. Typically, the crust is leavened with yeast at a level of 0.5-3% (flour basis). In fresh baked settings or par baked products, yeast raised pizza crusts are very successful. However, where and when consumers are eating pizza is changing. Now the consumer wants to bake their pizza at home and see it rise in the oven. With yeast as the leavening source, the oven must be preheated and requires long bake periods to make the finished product. Pizza crust which is chemically leavened can be placed directly from the freezer or refrigerator into a cold oven and be ready to serve in less than 20 minutes. Another advantage for chemical leavening over yeast leavening is the fact that leavening chemically is much more stable and tolerant of adverse storage conditions than yeast. Currently, the primary use of chemical leavening in the pizza industry is for frozen ready to bake pizza. But because chemical leavening is more stable than yeast – there is no reason it could not be used for refrigerated pizza doughs or even at the local mom & pop pizzeria.

Bicarbonate Functionality

Proper use of sodium bicarbonate (SBC) in self-rising pizza doughs can result in:

- More ‘baked from scratch’ texture

- Faster home preparation (box to the table time)

- Improved storage stability under refrigerated/frozen storage conditions

- More consistent crust volume

- More consistent crust color

Bicarbonate Recommendation

Sodium Bicarbonate Grade 1 Powdered:

Dissolves rapidly to assure quick, complete availability for reaction with the acid ingredients.

Sodium Bicarbonate Grade 1 TFF:Treated with tricalcium phosphate to improve flow quality. Dissolves rapidly to assure quick, complete availability for reaction with the acid ingredients.

Sodium Bicarbonate Grade 2 Fine Granular:The narrow particle size distribution of Grade 2 facilitates rapid uniform blending. This grade is recommended for those products where minimal leavening during mixing and holding is desired. It is also recommended for products where pre-reaction during preparation can be a problem. It is very useful in refrigerated and frozen doughs to limit pre-reaction with acid ingredients during storage.

Sodium Bicarbonate Grade 4 Granular:Coarser particle size delays the solubility and makes it useful in refrigerated doughs to limit pre-reaction with the acid ingredients.

Flow K™ Potassium Bicarbonate:Potassium bicarbonate performs exceptionally well as a replacement for sodium bicarbonate in most chemically leavened products. For equivalent CO2 release, 20% more potassium bicarbonate must be used.