Reducing Sodium in Baked Goods with Potassium Bicarbonate

Sodium Reduction in Baked Goods

The current national focus on sodium reduction is driving a trend among food companies to reduce the sodium content of their products. By promoting achievement of sodium reduction targets, companies can differentiate their products and increase market share.

Changing the sodium content of foods can affect flavor, texture and other characteristics. Baked goods in particular pose unique challenges. However, manufacturers now have several alternatives for successfully lowering the sodium content of their products without sacrificing quality

Salt Reduction

Reducing the amount of salt used to flavor baked goods can alter their taste, but it is often the simplest and most cost-effective strategy. A gradual reduction, made in stages over time, can be a useful way to decrease sodium content without driving away consumers.

Salt Substitution

A variety of salt substitutes are available to makers of baked goods. However, they may have unpleasant impacts on flavor – as well as higher costs.

Chemical leavening: Non-sodium alternatives

Nonsodium leavening acids offer opportunities to reduce sodium loading, but formulators must be aware of potential impacts on the rate of reaction. After salt, sodium bicarbonate is the primary contributor of sodium in chemically leavened baked goods.1Ammonium bicarbonate can be used in place of sodium bicarbonate, but its use (unneutralized) is limited to products with a final moisture content of less than 5%; in higher-moisture foods, retained ammonia may negatively affect flavor.

Another alternative is potassium bicarbonate, which reacts in a very similar way to sodium bicarbonate and can partially or completely replace it in a wide variety of baked goods. Church & Dwight Co, Inc. produces food-grade potassium bicarbonate under the brand name Flow K™.

Flow K™ Potassium Bicarbonate

This is a food-grade product comprising potassium bicarbonate USP and a small amount of magnesium oxide USP included as a flow aid to assure excellent storage and handling properties.

Potassium Bicarbonate USP

Potassium bicarbonate without a flow aid is available from Armand Products Company, a joint venture in which Church & Dwight Co., Inc. is a partner.*

Benefits of Potassium Bicarbonate

Health

Potassium’s vital role in human health – including the proper functioning of muscle tissue, bones and kidneys – is well recognized. In addition, the potential negative health impacts of excess sodium – including hypertension – are familiar to the medical community and many consumers. In 2000, the FDA approved a health claim for potassium stating that “diets containing foods that are a good source of potassium and that are low in sodium may reduce the risk of high blood pressure and stroke.”2 This claim can only be applied to foods that are low in sodium (i.e., products containing no more than 140 mg per reference amount customarily consumed (RACC)). Recent research has also revealed that consumers recognize the value of potassium in their diets and are supportive of potassium supplementation of food products.2

By partially or completely replacing sodium bicarbonate with potassium bicarbonate in baked goods, their sodium content can be significantly reduced. Thus, the use of Flow K™ potassium bicarbonate presents an opportunity to promote the dual health benefits of increased potassium and reduced sodium.

Flavor

Unlike other potassium sources, Flow K™ potassium bicarbonate has no metallic or fishy taste; can enhance the sweetness of sugar and other sweeteners; and mitigates the bitter aftertaste often associated with artificial sweeteners. Compared to sodium bicarbonate, it can actually have a sweetening effect on baked goods.

Versatility

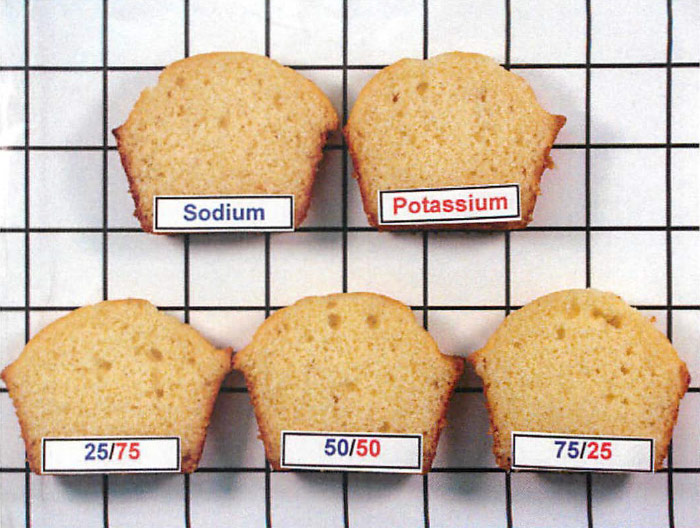

Flow K™ can be used in place of sodium bicarbonate as a leavening agent in a wide variety of baked goods, including biscuits, muffins, cookies, cakes and pancakes.

Compatibility

Flow K™ potassium bicarbonate is generally compatible with other food ingredients such as salt, sugar, starch gum, guar gum, and oil; is soluble in water; reduces viscosities formed with xanthan gels; has significant buffering capacity; and releases carbon dioxide when reacted with an acid or exposed to temperatures greater than 100° C.

Performance

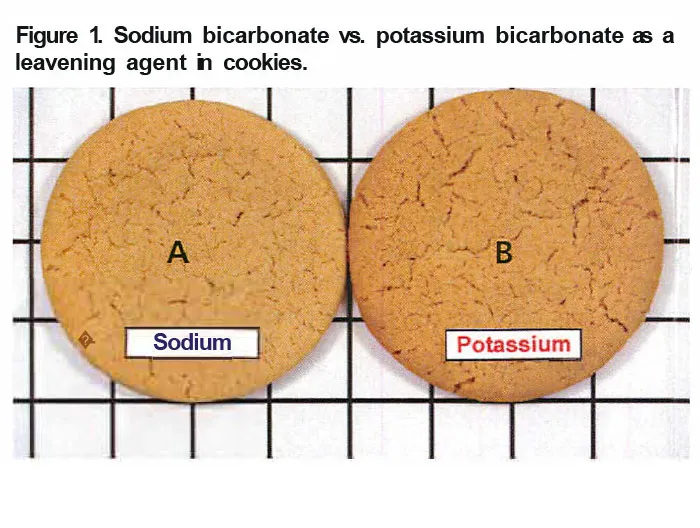

When compared to sodium bicarbonate, Flow K™ potassium bicarbonate performs as well or better in terms of the dimensions, volumes and appearance of baked goods. In one study, cookies leavened with Flow K™ had increased diameter and/or height and improved browning as compared to those leavened with sodium bicarbonate.3 (see Figure 1.)

Leavening with potassium bicarbonate (B) yields cookies with increased diameter and/or height, golden brown color and sweeter flavor as compared to leavening with sodium bicarbonate (A).

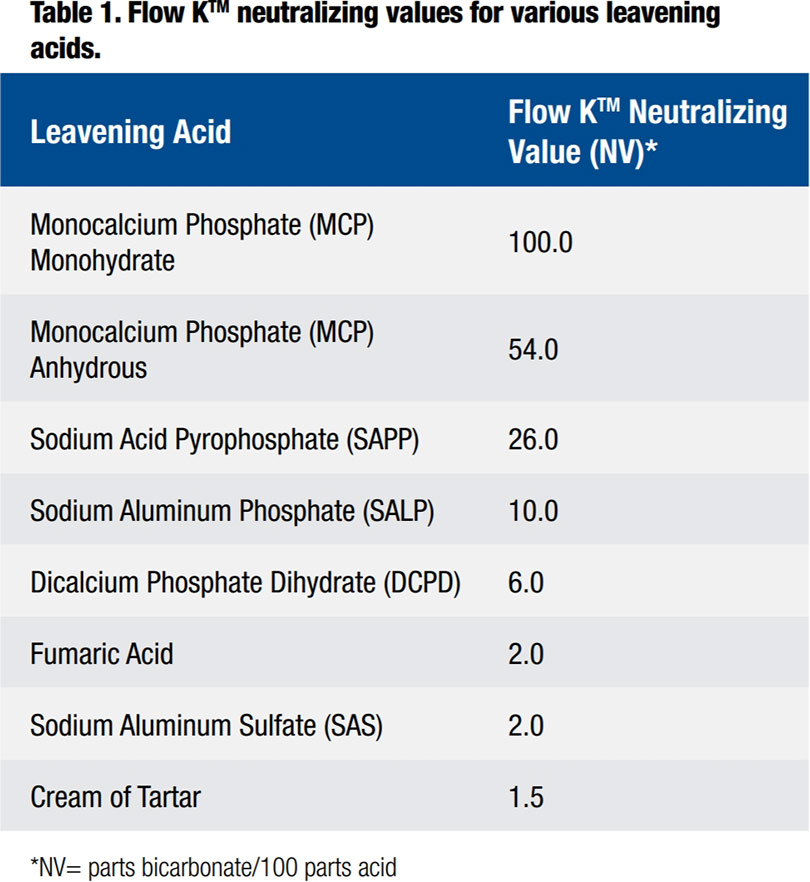

Replacing Sodium Bicarbonate with Flow K™ Potassium Bicarbonate

When substituting Flow K™ potassium bicarbonate for sodium bicarbonate in a formula for baked goods, 19% more potassium bicarbonate (by weight) is needed to yield equivalent carbon dioxide release. To calculate the total amount of Flow K™ needed in a specific recipe or formulation, simply determine the amount of sodium bicarbonate to be replaced, then multiply that amount by 1.19. There is no need to adjust the leavening acid type or level. (See Table 1. for a list of Flow K™ neutralizing values for various leavening acids.)

*Sample quantities of either product can be obtained by ordering on their respective websites, www.ahperformance.com, www.armandproducts.com.

References: 1. Gorton L. Leavening’s new low-sodium math. Baking & Snack. June 2010; 32(5):51-57. 2. Insights for Marketing. Final Report: Potassium Nutrition Consumer Caravan Survey. Church and Dwight Company internal document. October 2001. 3. Moore T. Evaluation of proprietary bicarbonate blends in bakery foods. AIB International Research Report. July 2008.