Cookies – Bicarbonate Applications

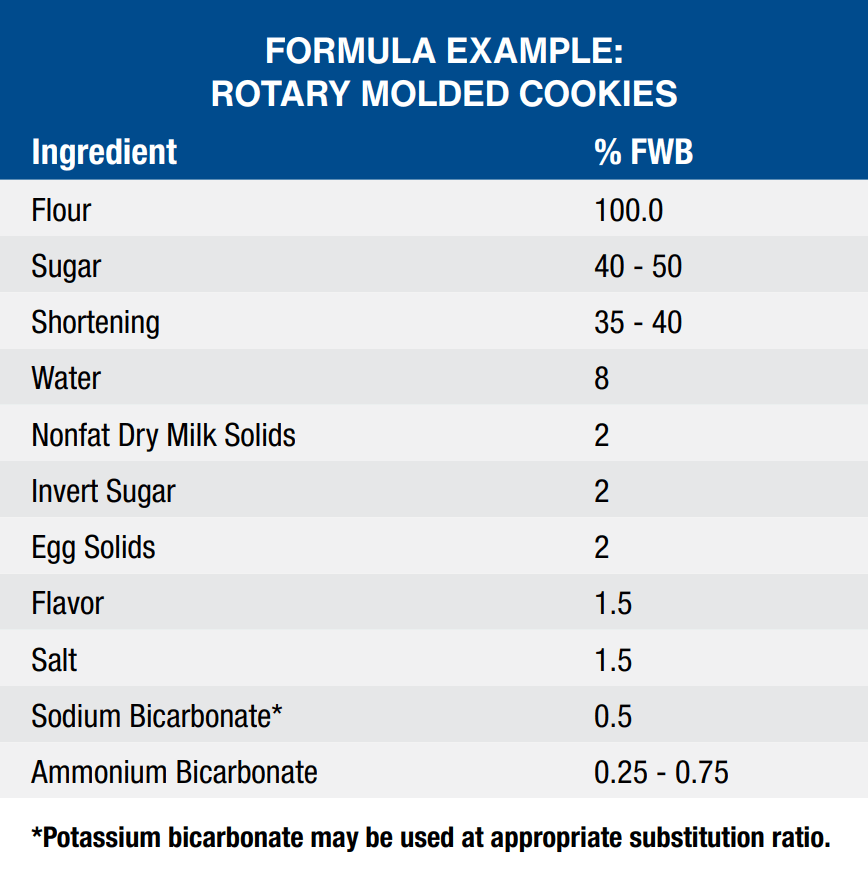

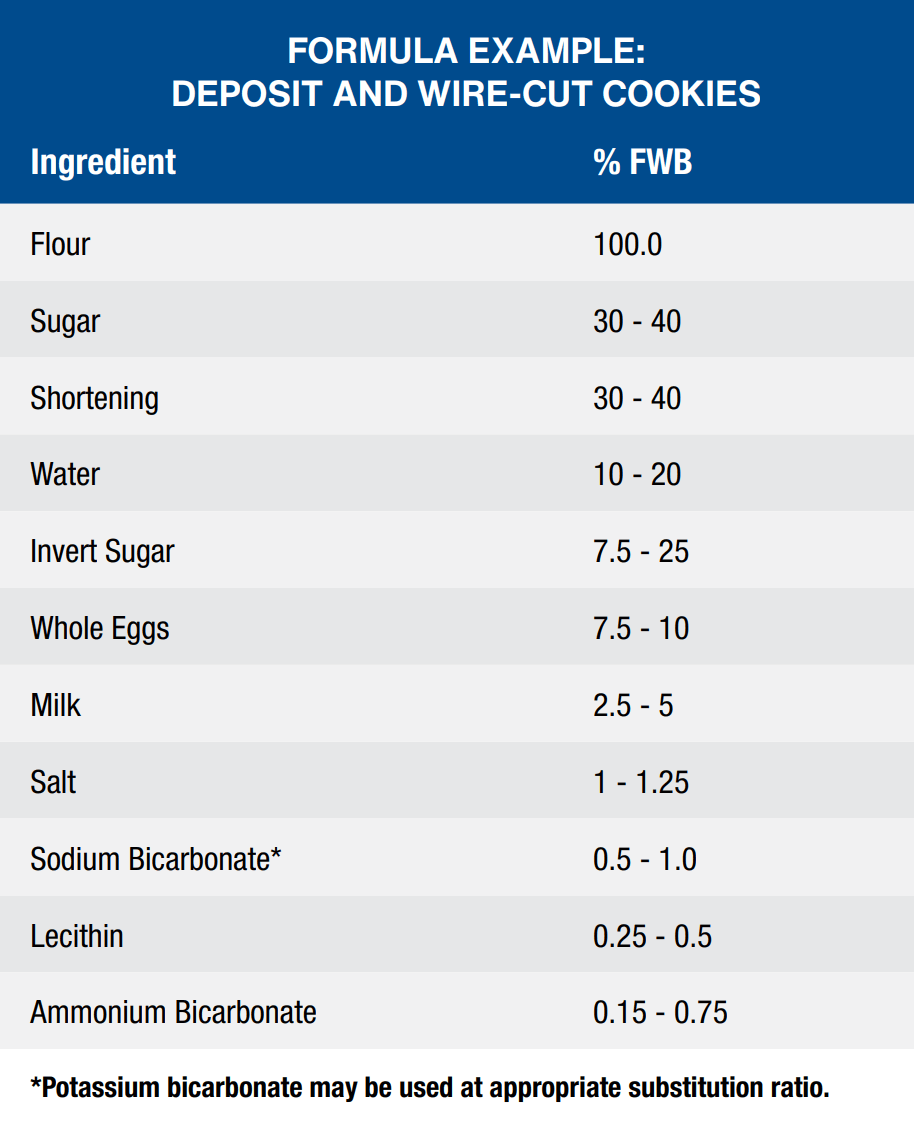

Cookies are made from doughs containing high levels of fat or sugar or both. Cookies can be classified into several categories depending on the type of forming machine used during its production: rotary molded cookies; extruded cookies (bar press and wire cut); and deposited cookies. The rheological properties of the cookie dough must conform closely to the needs of the forming and shaping machines being used. Deposit cookie doughs consist of a rich formula with a batter-like consistency which flows through nozzles directly onto the oven band. Wire-cut and bar-type doughs range in consistency from soft cake batters to stiff doughs. They must possess adequate cohesiveness to hold together as they are extruded through orifices, yet they must be relatively non-sticky and short enough so that they separate cleanly when cut by the wire as in wire cut or extruded from the hopper as in bar type. Rotary molded cookie doughs need to be firm and dry as the dough is compressed into dies embossed on the surface of a cylinder.

For most cookies, it is very important to control the diameter and thickness (spread) of cookies within a narrow range. The use of sodium, potassium and ammonium bicarbonate contribute to the physical attributes of the cookie such as height, diameter, surface cracking and grain. Bicarbonates also function to control the pH of the system which impacts the flavor and color of the cookie.

Bicarbonate Recommendation

Sodium Bicarbonate Grade 1 Powdered:

Dissolves rapidly to assure quick, complete availability for reaction with the acid ingredients.

Sodium Bicarbonate Grade 1 TFF:

Treated with tricalcium phosphate to improve flow quality. Dissolves rapidly to assure quick, complete availability for reaction with acid ingredients.

Sodium Bicarbonate Grade 2 Fine Granular:

The narrow particle size distribution of Grade 2 facilitates rapid, uniform blending. This grade is recommended for those products where minimal leavening during mixing and holding is desired.

Flow K™ Potassium Bicarbonate:

Potassium bicarbonate performs exceptionally well as a replacement for sodium bicarbonate in most chemically leavened products. For equivalent CO2 release, 20% more potassium bicarbonate must be used.

Ammonium Bicarbonate:

ABC reacts rapidly in the presence of moisture and/or heat to release CO2 and NH3 gases which contribute to leavening. Use of ABC without a leavening acid is limited to products whose final moisture is < 5% so the ammonia gas can bake out.